Description

Descriptions

38DL PLUS® Ultrasonic Thickness Gauge:

Advanced Features, Simple Operation, Rugged, Reliable

The 38DL PLUS is an innovative instrument that signals a new era in ultrasonic thickness gauging. Ideally suited for almost every ultrasonic thickness application, this handheld thickness gauge is fully compatible with a full line of dual and single element transducers. The versatile 38DL PLUS can be used in applications ranging from wall thinning measurements of internally corroded pipes with dual element probes to very precise thickness measurements of thin or multilayer materials with single element transducers.

The 38DL PLUS comes standard with many powerful but easy-to-use measurement features and a host of application-specific software options. Its sealed case is designed to meet IP67 requirements to withstand the rigors of very wet or dusty environments. The color transflective VGA display provides superior readability from bright sunlight to complete darkness. It features a simple, ergonomic keypad that can be operated with the left or right hand for easy access to all functions.

Key Features

|

|

What Makes This Thickness Gauge Different From Others?

The 38DL PLUS is designed to meet the challenges of demanding applications and built to withstand tough conditions in the field and on the production floor. Whether you work in very wet or dusty conditions, cold or hot climates, or bright or dark areas, the 38DL PLUS can handle any inspection job. Need an instrument tough enough to tolerate shocks, drops, and rough handling? The 38DL PLUS with its protective rubber boot and designed for IP67 rating is your answer.

Designed for Easy Operation

38-Link™ Wireless Communication Adaptor

| The optional 38-Link wireless adaptor enables any existing 38DL PLUS thickness gauge to send and receive data using Bluetooth® or wireless LAN*.

The 38-Link adaptor provides three powerful wireless communication capabilities:

For more details, see the 38-Link page, or download the 38-Link brochure. *Wireless LAN and Bluetooth dongle availability depends on your region. Contact your local Olympus sales representative for more information. |

|

Data Logger and PC Interface

The 38DL PLUS has a full-featured internal bidirectional alphanumeric data logger that is designed to easily collect and transfer thickness readings and waveform data.

|

|

GageView™

|

Onboard DB Grid View with three programmable colors |

Standard Package

| 38DL PLUS digital ultrasonic thickness gauge, AC or battery, 50 Hz to 60 Hz Kits available with standard dual element transducers

|

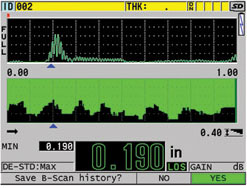

Measurement features: THRU-COAT, Thru-Paint Echo-to-Echo, EMAT compatibility, Min./Max. mode, two alarm modes, differential mode, B-scan, Application Auto-Recall, temperature compensation, Average/Min. mode |

Specifications

| Measurements | Dual element transducer measurement mode | Time interval from a precision delay after the excitation pulse to the first echo |

|---|---|---|

| THRU-COAT® measurement | Measurement of true metal and coating thicknesses with a single back-wall echo (with D7906-SM and D7908 transducers) | |

| Thru-Paint Echo-to-Echo | Time interval between two successive back-wall echoes to eliminate paint or coating thickness | |

| Single element transducer measurement modes | Mode 1: Time interval between the excitation pulse and the first back-wall echo Mode 2: Time interval between the delay line echo and the first back-wall echo (with delay or immersion transducers) Mode 3: Time interval between successive back-wall echoes following the first interface echo after the excitation pulse (with delay line or immersion transducers) Oxide: optional Multilayer mode: optional |

|

| Thickness range | 0.080 mm to 635.00 mm (0.003 in. to 25.000 in.) depending on material, transducer surface conditions, temperature, and selected configuration | |

| Material velocity range | 0.508 mm/μs to 13.998 mm/μs (0.020 in./μs to 0.551 in./μs) | |

| Resolution (selectable) | Low: 0.1 mm (0.01 in.) Standard: 0.01 mm (0.001 in.) High Resolution (optional): 0.001 mm (0.0001 in.) |

|

| Transducer frequency range | Standard: 2.0 MHz to 30 MHz (-3 dB) High Penetration (optional): 0.50 MHz to 30 MHz (-3 dB) |

|

| General | Operating temperature range | -10 °C to 50 °C (14 °F to 122 °F) |

| Keypad | Sealed, color-coded keypad with tactile and audible feedback | |

| Case | Impact-resistant and water-resistant, gasketed case with sealed connectors. Designed for IP67. | |

| Dimensions (W x H x D) | Overall: 125 mm x 211 mm x 46 mm (4.92 in. x 8.31 in. x 1.82 in.) | |

| Weight | 0.814 kg (1.80 lb) | |

| Power supply | AC/DC adaptor, 24 V; lithium-ion battery 23.760 Wh; or 4 AA auxiliary batteries | |

| Battery life, lithium-ion | Operating time: minimum 12.6 h, 14 h typical, 14.7 h maximum Fast charge: 2 h to 3 h | |

| Standards | Designed for EN15317 | |

| Display | Color transflective VGA display | Liquid crystal display, display area 56.16 mm x 74.88 mm (2.2 in. x 2.95 in.) |

| Rectification | Full wave, RF, half-wave positive, or half-wave negative | |

| Inputs/Outputs | USB | 1.0 client |

| RS-232 | Yes | |

| Memory card | Maximum capacity: 2 GB External microSD memory card | |

| Video output | VGA output standard | |

| Internal Data logger | Data logger | The 38DL PLUS identifies, stores, recalls, clears, and transmits thickness readings, waveform images, and gauge configuration information through the standard RS-232 serial port or USB port. |

| Capacity | 475,000 thickness measurements or 20,000 waveforms with thickness measurements | |

| File names, IDs, and comments | 32-character file names and 20-character alphanumeric location codes with four comments per location | |

| File structures | Nine standard or custom application-specific file structures | |

| Reports | On-gauge reporting of summary with statistics, Min./Max. with locations, Min. review, file comparison, and alarm report |

Software Options

38DLP-OXIDE (U8147014): Code-activated Internal Oxide measurement software

38DLP-HR (U8147015): Code-activated High Resolution measurement software

38DLP-MM (U8147016): Code-activated Multilayer measurement software

38DLP-HP (U8147017): Code-activated High Penetration (low frequency) measurement software

38DLP-EBSCAN (U8147018): Encoded B-scan software

Optional Accessories

38DLP/EW (U8778348): Three-year warranty

1/2XA/E110 (U8767104): Filter adaptor for E110-SB EMAT transducer

38-9F6 (U8840167): RS-232 cable

38-C-USB-IP67 (U8800998): USB cable for IP67 sealed operation

38DLP/RFS (U8780288):Foot switch, factory installed

HPV/C (U8780124): Digital caliper for thickness input for velocity measurements

38DLP-V-CC (U8840172): Cable for digital caliper

EPLTC-C-VGA-6 (U8840035):VGA output cable

MICROSD-ADP-2GB (U8779307): 2 GB External microSD memory card

BSCAN-ENC (U8779522): Encoded B-scan buggy

38DL–ENC-CBC-10 (U8840168): 10 ft encoder cable

Reviews

There are no reviews yet.